The Comprehensive Guide to Liquid Mercury Manufacturing

Introduction to Liquid Mercury

Liquid mercury has been integral to various industrial applications for centuries. Its unique properties, including its high density and ability to conduct electricity, make it a valuable resource in numerous fields. Understanding the role of a liquid mercury manufacturer is crucial for businesses and industries that rely on this versatile element.

How Liquid Mercury is Produced

The production of liquid mercury involves several stages, each critical to ensuring the quality and purity of the final product. The main sources of mercury come from mining operations, particularly in the following processes:

- Direct Mining: Extracting mercury-rich ores from the earth.

- Aerosol Collecting: Capturing mercury vapor from industrial processes.

- Recycling: Recovering mercury from used products like thermometers and batteries.

As a trusted liquid mercury manufacturer, Dschemek adheres to stringent guidelines ensuring that our production methods not only meet but exceed industry standards.

Applications of Liquid Mercury

Liquid mercury is widely used across various sectors. Its primary applications include:

- Industrial Processes: Used in the production of chlorine and caustic soda.

- Electrical Components: Essential in the manufacture of batteries and electrical switches.

- Scientific Research: Employed in thermometers, barometers, and other scientific instruments.

These applications highlight the necessity of sourcing high-quality mercury from reputable manufacturers like Dschemek, ensuring reliability and performance in every product.

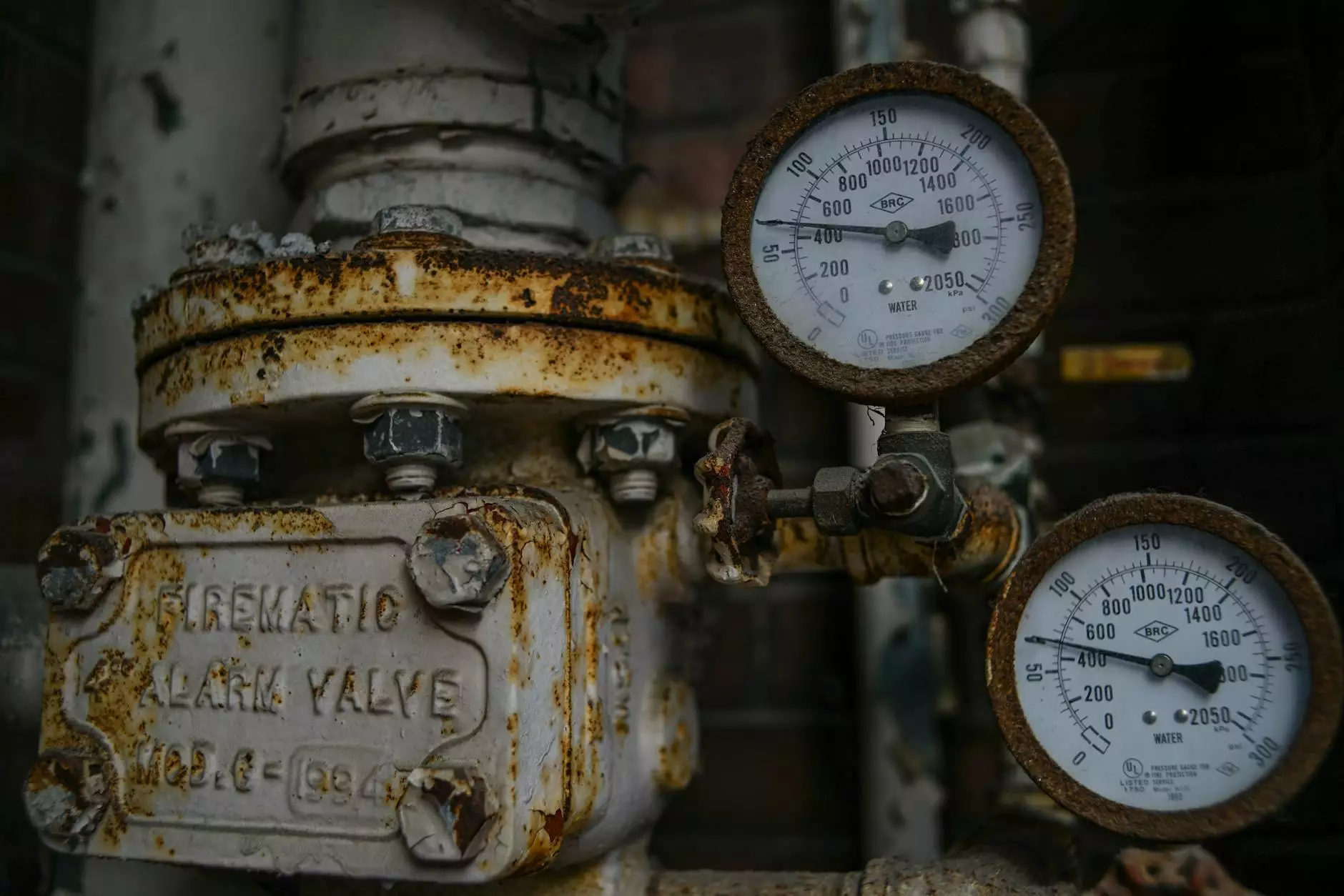

Quality Control in Liquid Mercury Manufacturing

Quality control is paramount in the manufacturing process of liquid mercury. Manufacturers must implement rigorous testing and monitoring protocols to guarantee the purity and reliability of their products. This includes:

- Purity Testing: Conducting assays to determine mercury content.

- Impurity Monitoring: Checking for trace contaminants that could affect product performance.

- Certification: Providing proper certifications that validate the quality of the mercury processed and sold.

At Dschemek, we prioritize quality above all else, ensuring that our customers receive only the best liquid mercury available in the market.

Environmental Considerations

One of the significant challenges facing the liquid mercury industry is its environmental impact. Mercury is a toxic substance, and its misuse can lead to severe ecological consequences. Responsible liquid mercury manufacturers take measures to minimize environmental damage, such as:

- Proper Waste Management: Ensuring that mercury waste is disposed of safely and in accordance with regulations.

- Emission Controls: Utilizing technologies to limit mercury emissions during production.

- Environmental Audits: Conducting regular assessments to ensure compliance with environmental standards.

As part of our commitment to sustainability, Dschemek continuously seeks innovative ways to minimize our carbon footprint while providing quality liquid mercury.

Choosing a Trustworthy Liquid Mercury Manufacturer

Selecting a reliable manufacturer is crucial for businesses that require liquid mercury. Here are key factors to consider:

- Reputation: Researching the manufacturer’s history and customer feedback.

- Certifications: Ensuring they have relevant certifications that attest to their quality and safety standards.

- Customer Support: Assessing their willingness to provide information and support post-purchase.

At Dschemek, we pride ourselves on our reputation as a premier liquid mercury manufacturer, committed to excellence and customer satisfaction.

The Future of Liquid Mercury Manufacturing

The future of liquid mercury manufacturing is evolving, driven by environmental regulations and advances in technology. Manufacturers are now exploring alternative and sustainable sources of mercury, including:

- Green Chemistry: Utilizing eco-friendly chemical processes to reduce reliance on traditional mercury sources.

- Innovation in Recycling: Developing advanced methods for recycling mercury from used products.

- Global Partnerships: Collaborating internationally to create efficient supply chains and ensure responsible sourcing.

As industry leaders, we at Dschemek are keen to embrace these trends, ensuring our production processes are not only efficient but also environmentally responsible.

Conclusion

In conclusion, the role of a liquid mercury manufacturer is vital in today’s industrial landscape. Understanding the processes, applications, and responsibilities involved in manufacturing liquid mercury can help businesses make informed decisions. Dschemek remains a reliable partner for quality mercury, committed to excellence and sustainability. By choosing us, companies can trust that they are not only getting a superior product but also contributing to a more sustainable future.