The Revolution of Manufacturing: Understanding 3D Printer Hardware

In today's fast-paced technological world, the evolution of 3D printer hardware stands at the forefront of innovation in manufacturing. This technology has not only transformed how products are designed and produced but has also opened doors to unprecedented levels of customization and efficiency. In this article, we will delve deep into the world of 3D printing, exploring the essential components of 3D printer hardware, their applications, benefits, and their impact on various industries.

What is 3D Printing?

3D printing, also known as additive manufacturing, is a process that creates three-dimensional objects by layering materials based on a digital model. This remarkable technology contrasts sharply with traditional subtractive manufacturing, which involves cutting away material from a solid block. The ability to create complex geometries and intricate designs with minimal waste makes 3D printing an exciting avenue for innovation across various fields.

The Fundamentals of 3D Printer Hardware

Understanding the components of 3D printer hardware is crucial for both enthusiasts and professionals looking to leverage this technology. Here are the main components:

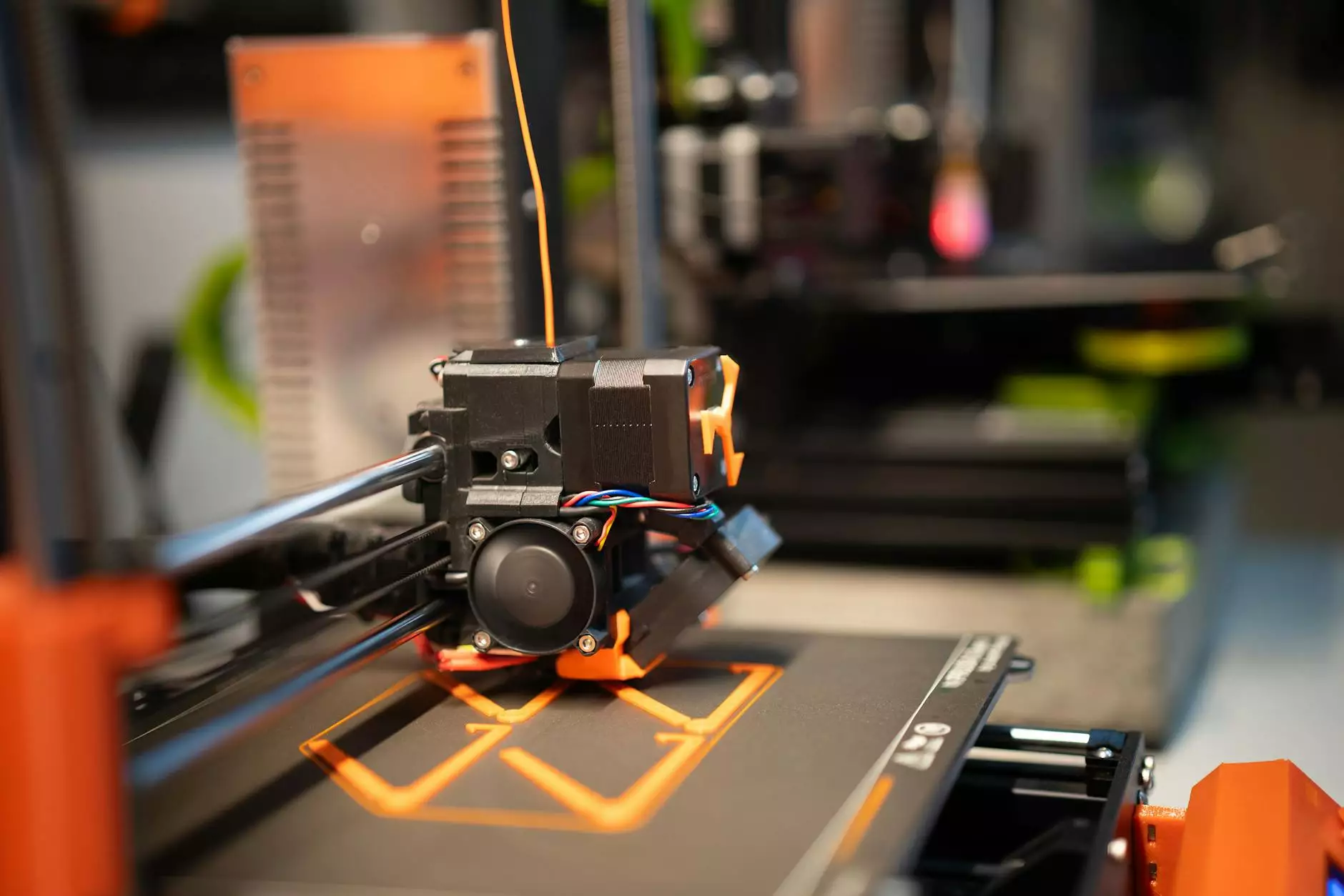

- Print Head: The print head is the heart of the 3D printer, responsible for depositing the material layer by layer. It can vary in design based on the technology used, such as FDM (Fused Deposition Modeling) or SLA (Stereolithography).

- Build Platform: This is the surface where the object is constructed. The build platform must be stable, capable of adhering to the material during the printing process, and often includes heated options to prevent warping.

- Frame: The frame provides structural integrity and support to the printer. It can be made from various materials and influences the printer's durability and precision.

- Motion System: The motion system is responsible for moving the print head or the build platform to create the object. It can include stepper motors, linear guides, and belts to ensure accurate movements.

- Control Board: This electronic component serves as the brain of the printer, overseeing operations and translating G-code into precise movements and instructions for the hardware.

- Power Supply Unit (PSU): The PSU powers the printer and needs to be compatible with the hardware components to ensure smooth functionality.

- Filament or Resin System: Depending on the type of printer, this system manages how the material is fed into the print head or how resin is cured to create the final object.

The Types of 3D Printer Hardware

Different types of 3D printers utilize various 3D printer hardware configurations, which caters to distinct applications and materials. Here are the most common types:

FDM Printers

Fused Deposition Modeling (FDM) is the most prevalent form of 3D printing, known for its affordability and ease of use. FDM printers use thermoplastic filaments that are heated and extruded through a nozzle. These printers are ideal for prototyping and home use.

SLA Printers

Stereolithography (SLA) employs a laser to cure liquid resin layer by layer. The resulting objects boast high precision and smooth finishes, making SLA printers exceptional for detailed applications such as jewelry design and dental models.

SLS Printers

Selective Laser Sintering (SLS) uses a powerful laser to sinter powdered materials, binding them together to form solid structures. SLS is favored for producing durable and complex geometries, often utilizing nylon or metal powders.

Binder Jetting

This method uses a liquid binding agent to fuse powder particles layer by layer. Binder jetting can produce intricate designs with a variety of materials, including metals and sand, making it suitable for casting applications.

The Applications of 3D Printing Across Industries

3D printing technology is making waves across numerous industries, leading to innovative applications and impactful advancements:

Automotive Industry

The automotive sector is harnessing the power of 3D printer hardware to create prototypes, tools, and even end-use parts. Manufacturers can reduce lead times significantly, allowing for rapid prototyping and testing, leading to faster product development cycles.

Aerospace Industry

Aerospace companies utilize 3D printing to manufacture lightweight and complex parts that contribute to efficiency and performance. The ability to produce components on-demand is revolutionizing supply chains in this highly regulated industry.

Healthcare

3D printing is reshaping the healthcare landscape through custom prosthetics, implants, and even bioprinted tissues. Medical professionals can create patient-specific solutions, significantly enhancing treatment outcomes and personalization.

Consumer Goods

The consumer goods sector is embracing 3D printing for customized products, from eyewear to footwear. This level of personalization meets the evolving demands of consumers, increasing engagement and satisfaction.

The Benefits of Investing in 3D Printer Hardware

Investing in 3D printer hardware brings a plethora of benefits for businesses and individuals alike:

- Cost-Effectiveness: 3D printing reduces material waste and lowers production costs, particularly for low-volume production and prototypes.

- Rapid Prototyping: Businesses can quickly iterate designs, testing functionality before mass production.

- Customization: Ability to create bespoke products tailored to customer specifications, enhancing competitiveness.

- Complex Geometries: 3D printing allows for complex structures that are often unachievable with traditional manufacturing.

- Reduced Time to Market: Speedy design and production cycles can lead to faster time-to-market for new products.

Challenges and Considerations in 3D Printing

Despite its many advantages, several challenges accompany the integration of 3D printer hardware in businesses:

- Material Limitations: While the range of materials is growing, not all materials are compatible with every printer, limiting options for some applications.

- Initial Investment: High-quality 3D printers can require significant upfront investment, which may be a barrier for smaller companies.

- Technical Expertise: Operating and maintaining advanced 3D printers requires a certain level of expertise, necessitating training and development.

- Intellectual Property Concerns: The ease of replication in 3D printing can pose threats to intellectual property, necessitating robust protective measures.

Future Trends in 3D Printing Technology

The future of 3D printer hardware is filled with exciting advancements and trends that promise to reshape industries further:

Increased Material Diversity

As research continues, the variety of materials suitable for 3D printing is rapidly expanding, including advanced metals, biocompatible materials, and even food items.

Integration with IoT

The integration of the Internet of Things (IoT) with 3D printing is enabling smarter manufacturing processes that can monitor performance and predict maintenance needs in real-time.

On-Demand Production

3D printing is progressing towards on-demand manufacturing, reducing the need for extensive warehousing and offering businesses the ability to produce only what they need when they need it.

Bioprinting Advances

The field of bioprinting is making strides toward the creation of functional human tissues and organs, which could revolutionize transplant medicine and drug testing.

Conclusion: Embrace the Future with 3D Printer Hardware

3D printer hardware represents a monumental shift in manufacturing capabilities, allowing for unprecedented levels of innovation, customization, and efficiency. As industries across the globe begin to recognize and harness the potential of this technology, the evolution of production processes will undoubtedly continue. By understanding and investing in 3D printing, businesses can position themselves for success in a rapidly changing landscape. Embrace the future of manufacturing with 3D printer hardware, and unlock the endless possibilities it offers.